Packaging Waste Statistics and Rollguard Solutions

Packaging is more than a protective layer — it’s a critical business decision. Inefficient, nonrecyclable packaging drives up material and disposal costs and exposes your business to regulatory risks and missed opportunities for savings.

With the EU tightening its packaging waste rules, companies that fail to adapt will face higher expenses and compliance headaches. Rollguard’s innovative fiber cradles are a smarter, sustainable packaging solution that helps cut costs, streamline operations and stay ahead of the EU’s new Packaging and Packaging Waste Regulation (PPWR) that will completely change the way packaging is designed, produced and disposed of.

Why Packaging Waste Is a Business Problem You Can’t Ignore

Packaging waste isn’t just an environmental issue — it’s a direct threat to your bottom line. Packaging waste statistics prove that every excess box, layer or nonrecyclable material adds up to higher costs and operational inefficiencies.

These are the facts:

- “Skinny design” reduces the overall box size and cubic volume of packaging. More products fit on shelves and in warehouses, driving top-line growth of 4–5% by increasing stock availability and reducing stockouts. It can also boost bottom-line growth by over 10% through reduced transportation costs, as more units are shipped per container or truck.

- Companies selling goods in the EU could pay 70–90% more than needed if they fail to use recyclable packaging and assign the correct eco-modulated fee.

- Research shows that 4 in 5 consumers will pay up to 9.7% more for goods made of recycled or eco-friendly materials, produced in a supply chain with a lower carbon footprint.

The Regulatory Landscape: What EU Packaging Waste Rules Mean for Your Business

The EU is leading the charge on packaging waste reduction, and the regulatory environment is changing rapidly. Staying compliant is essential for business continuity and market access.

The new regulations come with clear implementation timelines, with many requirements taking effect by 2030 and some as early as 2025. Failure to comply can result in significant consequences, including administrative fines, product recalls, bans on noncompliant packaging and even loss of access to the EU market. Authorities will conduct regular audits and require detailed reporting. It is essential for businesses to proactively adapt their packaging strategies to avoid costly penalties and disruptions.

EU Packaging and Packaging Waste Regulation (PPWR)

The PPWR is an all-encompassing regulation that will apply across all EU member states. It requires every type of packaging placed on the EU market to be fully recyclable in an economically viable way by 2030. The regulation also introduces strict restrictions on single-use plastics and mandates a reduction in unnecessary packaging volume and weight to reduce packaging waste.

It sets minimum recycled content requirements for plastic packaging and encourages the use of sustainable packaging solutions. Businesses must also ensure clear labeling for recyclability and provide data on packaging materials to authorities.

Circular Economy Action Plan

The EU’s Circular Economy Action Plan is a cornerstone of the European Green Deal. It aims to decouple economic growth from resource use through ambitious targets for reducing overall waste generation, increasing recycling rates and boosting the use of recycled raw materials in products and packaging.

The plan encourages businesses to design products and packaging for reuse, repair and recycling, and to implement take-back and recycling schemes. It also supports innovation and investment in circular business models, helping companies transition from linear to closed-loop systems.

Eco-design for Sustainable Products Regulation

This regulation expands the scope of eco-design requirements beyond energy-related products to include almost all physical goods, including packaging. Products must be designed from the outset for durability, repairability, reuse and recyclability to minimize their environmental impact throughout their life cycle.

For packaging, this means using materials that are easy to separate and recycle, reducing the use of hazardous substances and maximizing the use of recycled content. The regulation also introduces digital product passports to provide information on product composition and recyclability.

How Inefficient Packaging Eats Into Your Profits

The true cost of inefficient packaging is often hidden in your balance sheet, but its impact is real and ongoing. Inefficient packaging could be affecting your business in the following ways:

- Overspending on materials: Using more packaging than necessary or relying on expensive, nonrecyclable materials increases procurement costs.

- Labour and logistics costs: Bulky or complex packaging slows down packing and shipping, requiring more labour and increasing handling expenses.

- Waste disposal and landfill taxes: Nonrecyclable packaging leads to higher waste management costs, including landfill taxes.

- Lost revenue from missed recycling opportunities: Efficient, recyclable packaging materials can generate revenue or savings through recycling programmes, while wasteful packaging forfeits these benefits.

- Excess material costs: Void fill accounts for 40% to 58% of a typical box’s size. Over-packaging and use of fillers mean you’re paying for more materials than necessary, which quickly erodes profit margins.

- Higher shipping and disposal fees: Bulky, heavy or nonrecyclable packaging increases freight costs and leads to higher landfill or incineration fees.

- Operational inefficiency: Inefficient packaging takes up valuable warehouse space, complicates inventory management and slows down packing lines.

- Reputational and financial risks: Customers and partners increasingly expect sustainable practices. Failing to address packaging waste can damage your brand and lead to lost business opportunities.

Rollguard’s Fiber Cradles: A Smarter, Sustainable Packaging Solution

Rollguard’s fiber cradles are engineered to solve the business challenges of packaging waste. These solutions are efficient, protective and fully aligned with EU sustainability goals.

Material Efficiency

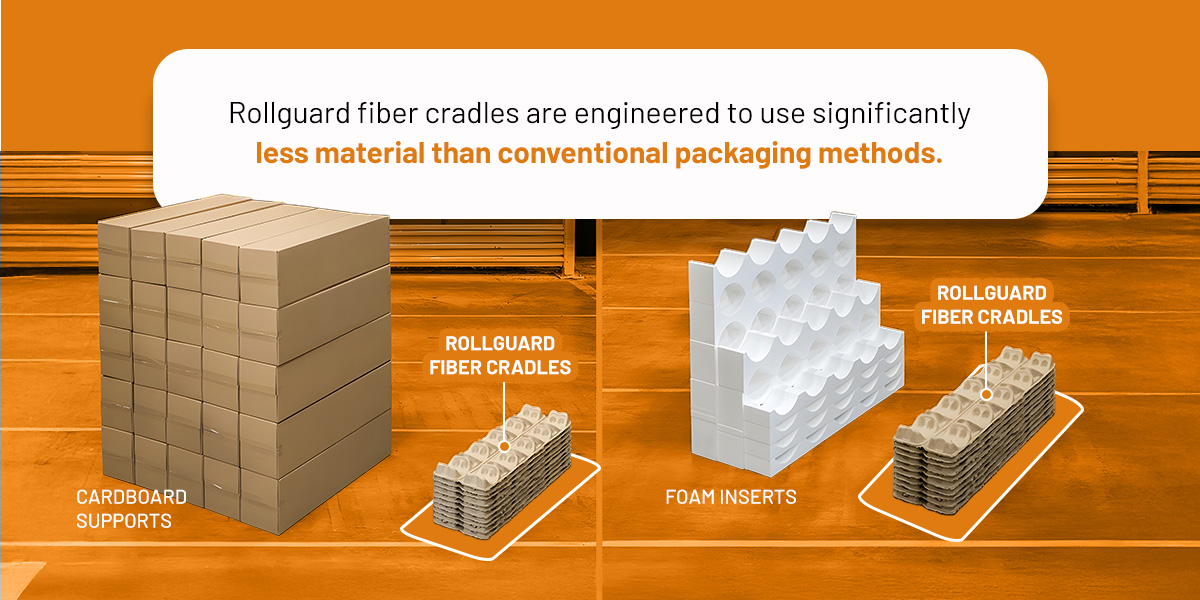

Rollguard fiber cradles are engineered to use significantly less material than conventional packaging methods like foam inserts or bulky cardboard supports. By precisely matching the shape and size of cylindrical products, fiber cradles eliminate unnecessary excess, helping lower the cost of raw materials and reducing the volume of packaging waste generated.

This streamlined approach means businesses spend less on procurement and benefit from lower disposal fees, supporting cost savings and sustainability goals.

Labour and Space Savings

The intuitive, stackable design of Rollguard fiber cradles simplifies the packing process. This means workers can quickly and securely load products with minimal training or effort. This efficiency reduces labour hours and the risk of packing errors.

The compact, nestable nature of the cradles means they take up less space in storage and during transit, freeing up valuable warehouse space and allowing more products to be shipped per pallet or container. The result is a leaner, more agile supply chain.

Compliance by Design

Manufactured in Germany to the highest quality standards, Rollguard’s fiber cradles are specifically designed to meet and exceed the latest EU packaging regulations.

Their recyclable fiber construction supports compliance with the PPWR and supports broader circular economy objectives. By choosing Rollguard, businesses can confidently demonstrate their commitment to sustainability and regulatory compliance, reducing the risk of fines or market restrictions.

Proven Results

Fiber pulp packaging benefits allow companies that have adopted Rollguard fiber cradles to consistently report tangible business benefits. These include measurable reductions in packaging waste, as less material is used and more is recycled. Many have also seen a drop in shipping costs, thanks to lighter, more compact loads, as well as improved operational efficiency due to faster packing and easier inventory management.

These real-world results highlight Rollguard’s value as a strategic partner for businesses seeking to optimise their packaging operations and achieve both financial and environmental targets.

How to Get Started: Choosing the Right Rollguard Solution

Transitioning to efficient, sustainable packaging is easier than you think. Rollguard offers these tailored solutions to fit your unique business needs:

- Product configurator: Quickly identify the best fiber cradle for your product dimensions, weight and shipping requirements.

- Customization options: Choose from a range of materials, sizes and load capacities to match your specific application.

- Expert support: Rollguard’s team provides guidance on optimising your packaging for efficiency, compliance and cost savings.

- Easy sampling and quoting: Request a sample or a personalized quote to see the benefits firsthand before making a commitment.

Reduce Waste, Cut Costs and Stay Compliant With Rollguard

Don’t let packaging waste drain your resources or put your business at risk. With Rollguard’s proven solutions, you can take control of costs and compliance.

Request your free sample today to experience the benefits of fiber pulp packaging for yourself or contact us to discuss your precise fiber roll cradle needs. Now’s the time to make the switch to sustainable packaging and secure your place in the circular economy.

Leave a Reply