Roll Cradles vs. Foam Inserts: Which Is Better for Protecting Cylindrical Products?

Choosing the right packing solution for cylindrical products helps increase their safety during transport, handling and storage. Discover the differences between roll cradles and foam insert packaging, including their definitions, materials, benefits and key factors to consider here.

What Are Roll Cradles?

Roll cradles are specialized packaging solutions designed to cradle and protect cylindrical products, such as paper rolls, medical films, fabrics and rolled roofing, during transportation and storage.

Roll cradles are made from various materials, including plastic, corrugated cardboard, foam and recycled fibrous materials. Each material offers different cushioning and protection for products during shipping and storage.

The key benefits of roll cradles include enhanced stability, ease of handling and their flexibility to accommodate cylindrical products of different sizes and weights.

What Are Foam Inserts?

Foam inserts are protective packaging materials designed to fit the shape of the products. They are commonly used for delicate or high-value items to prevent damage from impacts and vibration during transport.

Foam materials primarily include polyethylene and expanded polyethylene. Each offers different levels of density, resilience and cushioning ability.

The top benefit of foam inserts is that they can offer excellent cushioning properties.

Key Factors to Consider When Choosing Between Roll Cradles and Foam Inserts

It is crucial to understand the specific needs of your products and the conditions they’ll face in transportation and storage. Consider the points below:

- Product type and size: Roll cradles are ideal for oversized products like paper rolls, fabric tubes and cylindrical machine parts and offer premium support and stability. Comparatively, you can customize foam inserts to fit a wide range of shapes and sizes, making them suitable for smaller and more delicate items.

- Protection level needed: Roll cradles provide excellent stability and basic cushioning, suitable for products requiring support but less extensive shock absorption. Foam inserts offer superior cushioning and shock absorption for highly fragile products requiring additional protection.

- Storage and handling conditions: Consider the warehousing environments, including temperature and humidity. Roll cradles are typically more robust and can handle stacking and movement well, whereas foam inserts, which provide excellent protection, may require more careful handling to ensure against compression and possible damage.

- Cost and budget: Roll cradles often have a lower initial investment cost. They are also durable, meaning reduced replacement costs over time. Foam inserts are also effective but tend to have a higher upfront cost. However, they could help lower damage rates on more fragile products.

- Ease of use: Roll cradles are generally easier to set up and handle and help optimize space for storage and transport. Although foam inserts are customizable, they might require more time for setup and often take up more space, depending on the products’ dimensions.

Roll Cradles vs. Foam Inserts

When deciding between roll cradles and foam inserts for protecting your cylindrical-shaped products, weighing the advantages and disadvantages of each option is essential. Both roll cradles and foam inserts offer unique benefits.

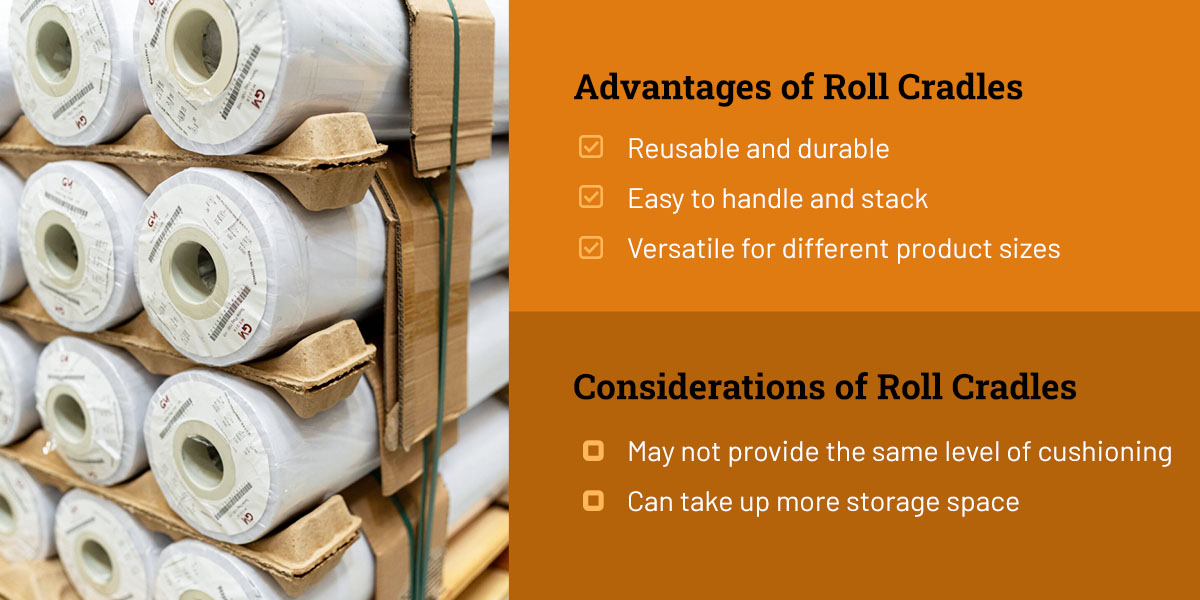

Advantages and Considerations of Roll Cradles

Roll cradles offer several advantages when protecting cylindrical products:

- Reusable and durable: Roll cradles are often made from robust materials like plastic, corrugated cardboard and strong fibrous materials, making them reusable and long-lasting — and, in certain instances, eco-friendly. Their durability reduces the need for frequent replacements and can lead to cost savings over time.

- Easy to handle and stack: Roll cradles are designed for easy handling and stacking, optimizing space in product storage and transport. This ease of use can help streamline logistics and reduce labor costs.

- Versatile for different product sizes: Roll cradles can accommodate various sizes and amounts of products, providing flexibility in your packaging options. Their versatility and adaptability make them suitable for multiple industries.

The considerations of roll cradles include the following:

- May not provide the same level of cushioning: While roll cradles offer exceptional stability, they may not provide the same cushioning and shock absorption level as foam inserts.

- Can take up more storage space: Roll cradles can be bulkier than foam inserts, which means they could take up more space when not in use.

Advantages and Considerations of Foam Inserts

The pros of foam inserts include:

- Shock absorption and cushioning: Foam inserts provide superior shock absorption and cushioning, making them ideal for protecting delicate or high-value items from potential impacts and vibrations during transport and handling.

- Lightweight and easy to handle: As they are lightweight, foam inserts are relatively easy to handle and transport, which also helps reduce labor costs and makes them convenient for various shipping and storage scenarios.

- Customizable to fit specific products: You can tailor foam inserts to fit the precise dimensions and shapes of the particular products in question, ensuring a secure, snug fit and enhancing the overall protection of products. Foam inserts are handy for oddly shaped items, which may have protruding components even if cylindrical.

The cons of foam inserts include:

- May require more frequent replacement: Foam inserts are prone to wear over time, especially with repeated use, which means they need to be replaced more frequently than products like roll cradles that use more durable materials.

- Might be less versatile for different roll sizes and shapes: Foam inserts may be less adaptable for different sizes and shapes of cylindrical products, as they are typically made to fit a particular shape. This could limit their use if you have various packing needs.

How to Make the Right Choice for Your Needs

Choosing between roll cradles and foam inserts requires a thorough assessment of your specific needs for your products. These are some tips and valuable questions to guide you through the decision-making process:

- Evaluate product requirements: Consider your cylindrical products’ type, size and fragility. What is the primary risk to your products during transportation, handling and storage?

- Assess protection needs: Determine the cushioning, stability and shock absorption level of your products. Do they require more stability, or is cushioning more essential?

- Think about ease of use: Evaluate the setup and handling efficiency. Which option will help streamline logistics and labor?

- Consider storage and handling: Think about your type of warehouse storage and environment and handling processes. Will the packaging be easy to stack and move, and is it suited to the various environments?

- Remember budget considerations: You should balance initial investment with long-term costs. What packaging best suits your budget?

- Consider hybrid solutions: Consider combining roll cradles and foam insert offerings to create the most effective solution.

Choose Rollguard to Secure and Stabilize Your Product During Shipping and Handling

When shipping cylindrical products, you want the best packaging solution, and Rollguard offers a range of custom roll cradles that can fit various product sizes. Our roll cradles provide a sustainable and durable solution for your packaging needs.

Browse our application examples to see how easy it is to use roll cradles in different scenarios. To discuss your precise fiber roll cradle needs or ask questions about our products, contact us today.

Leave a Reply