The Best Way to Stack Pallets

Inventory management is one of the most important aspects of managing a business. By arranging your products carefully, you can improve warehouse efficiency and meet distribution goals.

Distributors and warehouse officials need dependable pallet organization to keep products safe. It’s also important to use correct pallet stacking methods during distribution and inventory processes. Following the correct procedures can keep your employees safe and prevent products from damages. But many employees or warehouse officials can get confused about the proper stacking techniques.

Read on to learn more about how to stack pallets correctly.

How to Properly Stack Pallets

It’s essential to stack pallets correctly so that you can protect products from damage. Using the right techniques can keep employees safe and items secure.

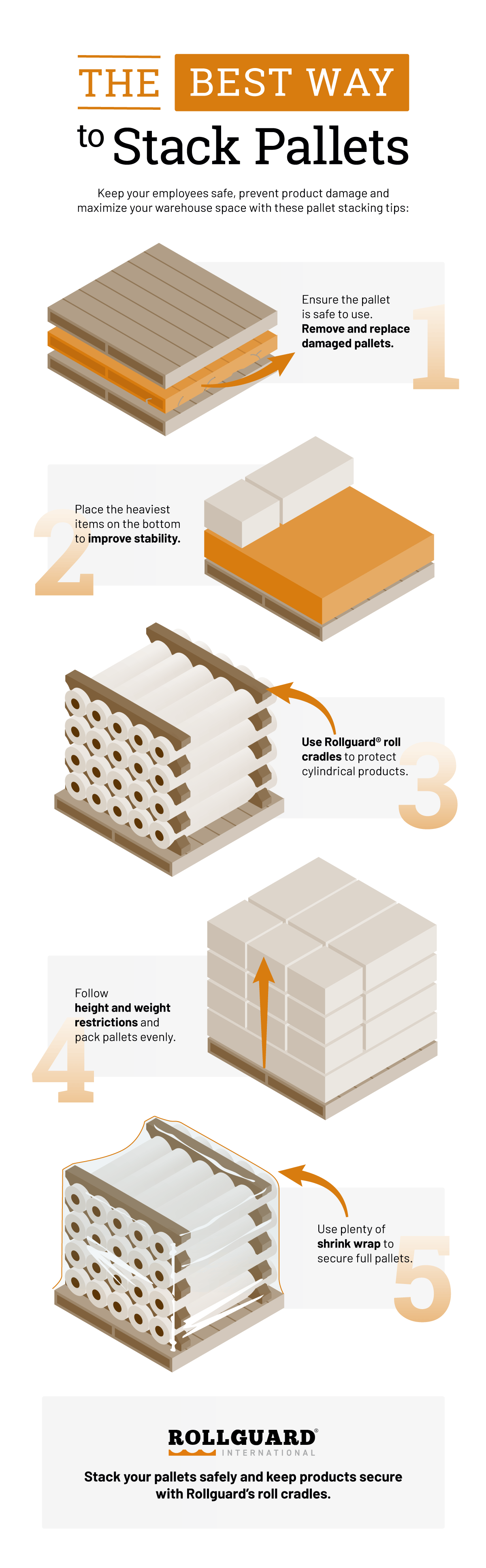

Here are five tips for ensuring your pallets are stacked properly:

1. Ensure the Pallet Is Secure

Your first step should be to make sure your pallets are secure and that they are not damaged or broken. If you find broken pallets, take them out of rotation as soon as possible. Damaged units lack essential stability and security, making moving pallets more dangerous. They could cause entire stacks to tip over, leading to damaged inventory and financial losses. Or, broken pieces like splinters could harm workers during transport.

Inspect pallets for faults like:

- Protruding nails

- Splinters

- Cracks

- Other visible damages

Instead of reusing damaged pallets, buy replacement units. Using damaged pallets could lead to product damage, resulting in more overall expenses. New pallets can help you create a safer work environment and prevent potential tip-overs.

2. Place the Heaviest Items on the Bottom

Another integral stacking rule is to place the heaviest items on the bottom of your pallets. With the heavier weight closer to the ground, you can create a lower center of gravity, which allows for more stability. And, keeping heftier items on the bottom prevents them from damaging more delicate products.

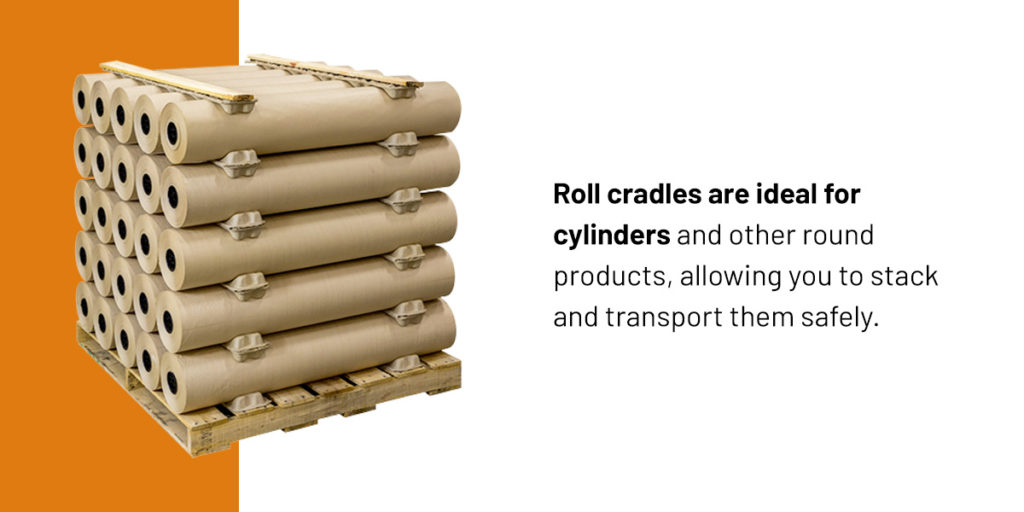

3. Use Roll Cradles for Rounded Products

Specific loading methods can also vary by your product’s shape. For instance, products with a rounded shape can sometimes present more challenges during placement. Some distributors stack cylinders in a pyramid structure, but this method can be unstable and lead to damaged products.

A great alternative to pyramid stacking is a roll cradle. Roll cradles are ideal for cylinders and other round products, allowing you to stack and transport them safely. Each has two conjoined sections that you can place on the top and bottom of your pallets. You can also fold roll cradles between layers on your pallet. The fiber cradles cushion the products and keep them in place during transportation.

Rollguard EU is a leading provider of roll cradles, offering an innovative and affordable way to stack round items. When you choose Rollguard’s roll cradles, you avoid the pyramid method and keep products secure. These easy-to-use tools can help you create a safer working environment.

These are other benefits of roll cradles:

- Prevents rolling: The biggest concern for round products is them rolling out of position. Their movement could compromise the entire pallet structure, causing the other cylinders to slide out of place. With roll cradles, the products fit precisely into grooves and stay secure during movement.

- Saves space: Roll cradles also save space in warehouses and distribution trucks. You can nest the cradles in one another, stacking pallets safely and effectively. In turn, you can have more room to package and produce items.

- Lowers costs: You can also lower expenses with roll cradles. Their optimized space allows you to pack more onto shipment trucks, preventing extra trips. They also use less packaging material, which can lessen your costs.

4. Maintain the Right Boundaries

Next, it’s important to follow the right stacking procedures. You should never go over height or weight limits when stacking pallets. Going too far over these limits could injure your employees or harm your products. Warehouse managers should keep track of their available space and weight and height restrictions to maintain a safe working environment.

You also shouldn’t exceed the limitations of warehouse machinery. For instance, employees should not overload forklifts, because the equipment might damage the products or fail altogether.

Additionally, you must stack all pallets evenly. Don’t allow for any overhanging materials or uneven weight distribution. Any form of uneven stacking could cause pallets to topple off forklifts or crash during transport. Avoid methods like pyramid stacking, which forms unstable bases.

5. Use Plenty of Shrink Wrap

Lastly, you should use shrink wrap after the pallets are in place. Shrink wrap can hold your pallets together securely, creating single units that are less likely to fall over when moved. It’s a relatively inexpensive material that adds a few layers of protection to your pallet. Use plenty of shrink wrap on your pallets, taking multiple passes from the top to the bottom. Wrapping each layer more than once can ensure even more security.

Benefits of Proper Pallet Stacking

Committing to the correct stacking methods can bring many benefits to warehouses, including:

- Optimized space: Using the proper stacking techniques can maximize your available space in the safest way possible. You can protect products and optimize storage in both warehouses and distribution vehicles. Options like roll cradles can nest, freeing up floor space for other tasks.

- Secure inventory: When you stack pallets correctly, you reduce the potential for inventory damages. Stable bases keep products from toppling over while in storage or shipment. You can keep your products in high-quality condition, allowing for more customer satisfaction after distribution.

- Safe workplace: Properly stacked pallets also contribute to a safer work environment. Pallets stay in place, lessening the possibility of injuring workers. Removing damaged pallets prevents harm from splinters or other dangerous materials. And the more organized your pallets are, the easier it is for workers to complete tasks.

Overall, following the correct stacking procedures can create a safer and more productive warehouse environment.

How Rollguard Can Help

Safe stacking techniques are crucial for warehouses. Roll cradles are excellent options for keeping products secure. At Rollguard, we understand the importance of safe stacking. We offer a variety of roll cradles to fit your exact pallet stacking requirements. These versatile and cost-effective options vary by material, size and design, so you’re sure to find the option that suits your needs.

Our roll cradles suit a wide range of applications, including:

- Agricultural film and fabrics

- Stretch wrap and shrink film

- Roofing and building materials

- Fabrics and textiles

- And more!

No matter your industry or application, Rollguard is here to help. To get started with Rollguard, check out our pallet configurator to find the product that fits your needs.

Leave a Reply